Filler, suitable as a filling material, in combination with glue, is used in applications like filling splitting wood throats, punctures, joining and closing torn component rabbets and for many more applications.

Applications:

Put on shifts of filler of approximately 2-3 mm thickness and then impregnate thoroughly with glue. To prevent filler from dropping through holes, just put a sheet of paper underneath.

Depending on the situation you may also put on glue first and then spread on filler. The second variant proved most effective particularly at welds. Make sure that the filling material is thoroughly soaked through with glue.

After two or three minutes the hardened joint can be processed mechanically, filled in, or varnished (laquered).

Filler is not toxic, does not damage the environment and can be disposed of together with household waste.

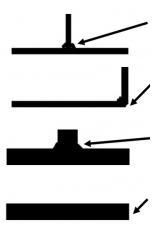

Application Examples for max1 filler

Place filler and soak thoroughly with max1.

The stability of this usually impossible joint can be obtained by using max1.

Knocked out or broken off materials can be refilled with filler and can then be repaired by reassembling using max1.

max1 and filler is most suitable to refill and replace broken off materials of any kind.